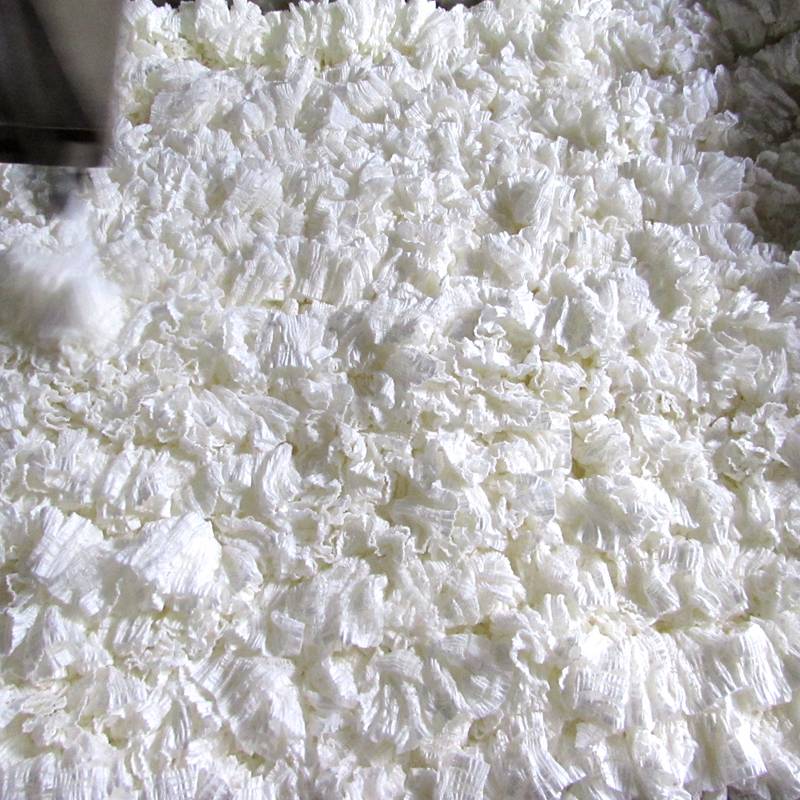

Acetate tow is additionally called cellulose acetate tow. It is made from acetate flakes or cleansed all-natural cellulose. All-natural cellulose responds with the acetic anhydride flakes to develop the powder. It is just one of the esters of cellulose. It is amongst the chemicals that are utilized in the cigarette market. These specialized solvents are acetate or acetic ester by-products. Ethyl acetate (ETAC) tow is made from Ethyl ethanoate. Ethyl acetate has a chemical formula C4H8O2. cellulose acetate, which is the acetic acid ester of cellulose.Diacetate (typically called acetate) is specified as cellulose acetate for which greater than 74% as well as less than 92% hydroxyl has actually been acetylated (level of esterification over 2.22 and also below Drapes gently as well as flexibly

These features emerge from the residential or commercial properties of acetate fiber. The residential or commercial properties of acetate fiber, compared to the residential properties of various other significant fibers. We can see that acetate fiber really feels all-natural and also mild on the skin since it is made from high pureness pulp. The fiber cross-section for each and every thread is arbitrary as well as multi-lobal, as well as has a reduced refractive index. These residential properties offer it the sophisticated gloss and also clear tinting that resemble silk. Acetate fiber likewise has a reduced Young's modulus than polyester or cotton, thus permitting it to curtain flexibly. On top of that, the modest degree of main dampness gain back (3% to 7%) and also multi-lobal cross-section produce a diffusion result with capillary activity. This subsequently provides the fiber a suitable level of water absorbency and also quick-drying efficiency. Contrasted to rayon and also various other fibers, acetate fiber additionally has better security for measurements as well as dimensions, along with solid pleating toughness, since it does not swell a lot in water.

Suitable water absorption and also quick-drying top qualities

Does not diminish quickly, so gives security for measurements and also dimensions

Solid pleating toughness (triacetate).

No fears of pilling.

Reasonably heat array for risk-free ironing.

Does not tarnish quickly, as well as spots are very easy to get rid of.

Really feels all-natural as well as is mild on the skin

Sophisticated gloss as well as chromogenic high quality

by integrating it with various other fibers that have enough toughness, such as polyester, it has actually ended up being feasible to make use of acetate fibers for functional applications. Polyester fiber has a varicolored look and also flexibility, so it can contribute to the structure of acetate fiber. The mix of both fibers can create weaved as well as woven material that really feels remarkable on the skin.

SPEEIFICATIOIN5

2.5Y/25000 2.5Y/30000 2.5Y/35000 2.7Y/35000 2.8Y/28000 2.8Y/35000 3.0Y/28000 3.0Y/29000 3.0Y/30000 3.0Y/32000 3.0Y/33000 3.0Y/35000 3.2Y/37000 3.3Y/35000 3.3Y/37000 3.5Y/34000 3.5Y/35000 4.0Y/35000 4.8Y/30000 5.0Y/25000 5.0Y/30000 5.8Y/16000 5.8Y/17000 6.0Y/28000 7.3Y/30000 8.0Y/28000

Technical Data Sheet of Acetate tow

| ITEM | RANG OF STANDARD | NUMERICALVALUR | TEST METHOD |

| Ktex | 25000-40000 | 3000 | YC/T169.1—2002 |

| Dtex | 2.5-8.0 | ±0.25 | YC/T169.2—2002 |

| Coil number/25mm | 22 | ±3 | YC/T169.3—2002 |

| Tension strength(N/Ktex) | ≥7 | ≥7 | YC/T169.5—2002 |

| Section figure of fiber | Y | Y | YC/T169.6—2002 |

| Moisture(%) | ≤6% | ≤6% | YC/T169.8—2002 |

| Oil content(%) | 0.8%—1.5% | 0.8—1.5 | YC/T169.9—2002 |

| Odor | Odorless | Odorless | YC/T169.10—2002 |

| Residual acetone content(%) | ≤0.006 | ≤0.006 | |

| TiO2 content(%) | ≥0.5 | ≥0.5 | YC/T169.11—2002 |