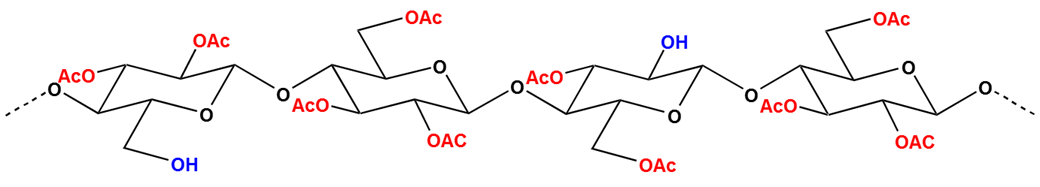

What is cellulose acetate?

Cellulose acetate is a product produced by a non-homogeneous reaction between cellulose and acetic anhydride, in the presence of a catalyst and other auxiliary reagents.According to its degree of substitution, cellulose acetate is divided into cellulose diacetate and cellulose triacetate. The degree of substitution (degree of substitution is an average number that refers to how many of the three hydroxyl groups on the cellulose unit are substituted) is 2.2-2.5 for cellulose diacetate and greater than 2.7 for cellulose triacetate. Cellulose acetate is a product produced by a non-homogeneous reaction between cellulose and acetic anhydride, in the presence of a catalyst and other auxiliary reagents.

Table 1. Conversion table of cellulose acetate substitution degree, acetic acid value and acetyl content

| Substitution degree | Acetic acid | Acetyl content | Substitution degree | Acetic acid | Acetyl Content | Substitution degree | Acetic Acid | Acetyl content |

| 1.6 | 41.9 | 30.0 | 2.18 | 51.6 | 37.0 | 2.58 | 57.3 | 41.0 |

| 1.67 | 43.2 | 30.9 | 2.24 | 52.5 | 37.6 | 2.63 | 57.9 | 41.5 |

| 1.75 | 44.6 | 32.0 | 2.28 | 53.1 | 38.0 | 2.68 | 58.6 | 42.0 |

| 1.83 | 46.0 | 32.9 | 2.32 | 53.7 | 38.5 | 2.74 | 59.3 | 42.5 |

| 1.92 | 47.5 | 34.0 | 2.37 | 54.4 | 39.0 | 2.79 | 60.0 | 43.0 |

| 2 | 48.8 | 35.0 | 2.42 | 55.1 | 39.5 | 2.85 | 60.7 | 43.5 |

| 2.05 | 49.6 | 35.5 | 2.45 | 55.5 | 39.8 | 2.91 | 61.4 | 44.0 |

| 2.09 | 50.2 | 36.0 | 2.47 | 55.8 | 40.0 | 2.96 | 62.0 | 44.5 |

| 2.14 | 51.0 | 36.5 | 2.52 | 56.5 | 40.5 | 3 | 62.5 |

44.8 |

From Nature

Cellulose acetate is an environmentally friendly natural modified material. Its raw material comes from pulp companies with good forest management. Good forest management means careful planting along with harvesting to ensure that the ecological environment is not destroyed.

In addition, during the production of cellulose acetate, we pay great attention to process optimization, such as solvent recycling and reduction of water and energy usage, in order to reduce the impact on the environment.

Degradability

Cellulose acetate is an environmentally friendly product that is more easily degradable compared to other polymeric materials. For cellulose acetate, its degradation includes photodegradation, chemical degradation and biodegradation. The degradation steps are usually divided into two steps.

Step 1: Deacetylation - i.e., hydrolysis, leading to a reduction in the degree of substitution.

The second step: depolymerization - and degradation of the glycosidic units, leading to a reduction in molecular weight.

Solubility

In general, the solubility of cellulose acetate depends on the level of substitution and the distribution of its intramolecular and intermolecular substitution. High degree of substitution, low solubility.

Compared to other cellulose esters (nitrocellulose, viscose cellulose, ethyl cellulose, etc.), cellulose acetate is slightly less soluble. Because of this, cellulose acetate has excellent chemical resistance. For cellulose triacetate, the typical solvent is methylene chloride. For cellulose diacetate, the solvent is mostly acetone.

Table 2. Solubility of cellulose diacetate with different types of solvents (〇 for soluble, Χ for insoluble)

|

Solvent species |

chemical |

Dissolution performance |

Solvent species |

chemical |

Dissolution performance |

|

esters |

acetic ether |

〇 |

The aliphatic class |

hexane, heptane |

Χ |

|

ethyl propionate |

Χ |

cyclohexane |

Χ |

||

|

ethyl lactate |

〇 |

alcohols |

alcohol |

Χ |

|

|

Ethylene glycol acetic ether acetate |

〇 |

isopropanol |

Χ |

||

|

ketone |

acetone |

〇 |

diacetone alcohol |

Χ |

|

|

methyl ethyl ketone |

〇 |

2-Methylene ethanol |

Χ |

||

|

hexone |

Χ |

other |

DMF |

〇 |

|

|

cyclohexanone |

〇 |

dimethyl sulfoxide |

〇 |

||

|

Cycloether class |

1,4-Dioxane |

〇 |

carrene |

〇 |

|

|

butylene oxide |

〇 |

chloroform |

〇 |

||

|

Ethylene glycol class |

glycol |

Χ |

1-Methyl-2-pyridine |

〇 |

|

|

Ethylene glycol acetate |

Χ |

Esterol mixture |

Ethyl acetate / ethanol, 75 / 25 |

〇 |

|

|

hexanediol |

Χ |

Ethyl acetate / ethanol l, 50 / 50 |

Χ |

||

|

Aromatic class |

Methene, xylene |

Χ |

Ethyl acetate / ethanol, 30 / 70 |

Χ |

Application of cellulose acetate

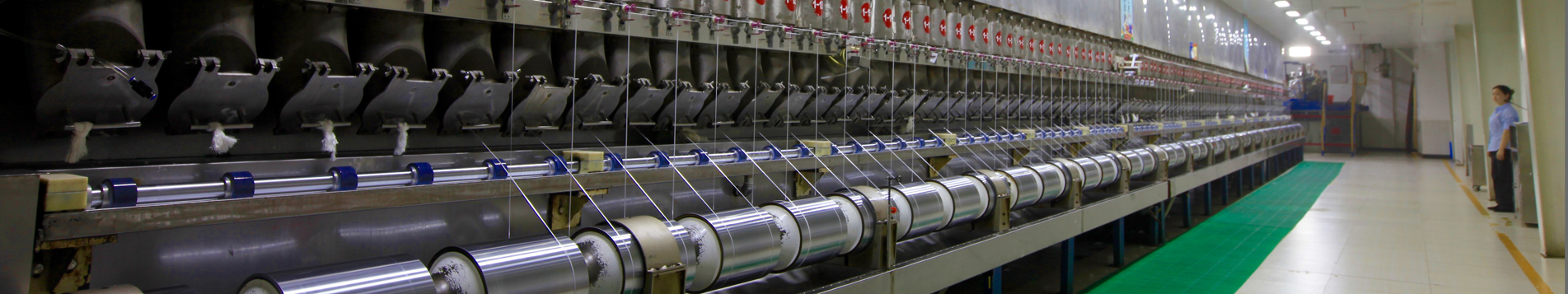

Different types of cellulose acetate have different application areas. The magic of cellulose acetate is that it can be used for soft yarn-like clothing fabrics and cigarette tow, thin liquid crystal display films, as well as hard and straight plastics; it can be used for processing processes at temperatures over 200°C, and also for dissolution processes at low temperatures.

English

English Español

Español Pусский

Pусский Tiếng Việt

Tiếng Việt 日本語

日本語 Deutsch

Deutsch Français

Français Türkçe

Türkçe العربية

العربية

Provide Us Your Specifications

Provide Us Your Specifications Custom Made For You

Custom Made For You Prompt Delivery

Prompt Delivery