"YC/T26-2008 tobacco cellulose diacetate tow" tobacco industry standard

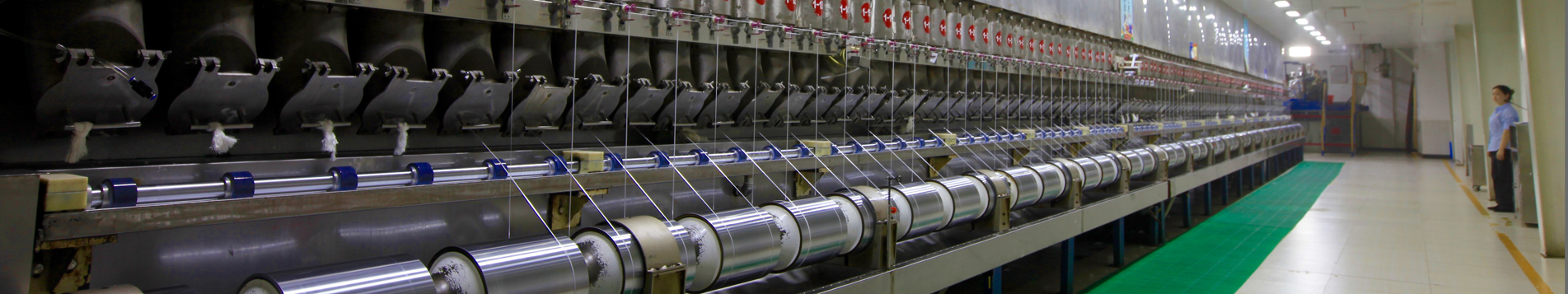

Adopting the international leading Daicel's latest cellulose diacetate tow manufacturing technology, it has outstanding advantages in slurry filtration technology, flexible spinning production, energy saving and high efficiency, etc., so that the product quality and usage performance can be greatly improved. This project production line has the following seven improvements on the basis of Daicel's original process technology.

1、The dissolution process adopts continuous dissolution process, and the DCS system is used to finely control the adding flow of various raw materials, which can avoid the undissolved vinegar flake particles from blocking the slurry transfer pump on the basis of reducing the labor load of operators and effectively improve the control level and product quality.

2、The titanium dioxide slurry preparation process adopts wet crusher instead of plate and frame filter press, which reduces the loss of titanium dioxide and improves the quality of slurry.

3、The filtration process adopts quantitative filtration technology instead of constant pressure filtration technology, and adopts single flow management to stabilize filtration flow rate, reduce filament breakage, achieve fine filtration and improve spinnability.

4, dilute acetone delivery method from intermittent batch delivery to continuous quantitative delivery, to avoid the fluctuation of dilute acetone concentration, and then stabilize the production conditions of the distillation process.

5、The spinning process adopts two different series of spinning machines, each series can operate independently, which can effectively meet the production needs of multi-specification products and has greater production flexibility.

6、DF oil emulsion process is changed from online mixing to trans-phase emulsification, so that the emulsion is evenly attached to the yarn bundle, reducing the amount of rolled stick flying hair.

7, acetone recovery process increased the air collection box and hygrometer, effectively reducing acetone loss.

SECHEA INDUSTRIAL LIMITED tobacco cellulose diacetate tow product quality in line with the "YC/T26-2008 tobacco cellulose diacetate tow" tobacco industry standard requirements, product specifications cover the range of: single filament linear density 1.67 ~ 8.89 dtex, tow linear density 2.222 ~ 5.556ktex, and according to customer We can design and supply vinegar fiber bundles according to customers' requirements.

English

English Español

Español Pусский

Pусский Tiếng Việt

Tiếng Việt 日本語

日本語 Deutsch

Deutsch Français

Français Türkçe

Türkçe العربية

العربية

Provide Us Your Specifications

Provide Us Your Specifications Custom Made For You

Custom Made For You Prompt Delivery

Prompt Delivery